Mastering the types of wire can mean all the difference between safety, efficiency, and industry compliance in the electrical and construction fields. Wire is the lifeline to so many systems, carrying currents that power our homes, industries, and technologies. It shall, therefore, thoroughly explore a range of wires, their unique properties, applications in various sectors, and considerations for optimum usage.

⚠️ Don’t Compromise on Safety! Get Certified Explosion Proof Cable Glands Now! ⚠️

In critical industrial zones, a faulty cable gland can lead to disastrous failures. Protect your assets, personnel, and compliance with our trusted, certified explosion-proof cable glands.

- ⚡️ Instant protection against fire, dust, and moisture

- ✅ Certified by ATEX, IECEx, and PESO for global standards

- 🛠️ Engineered for the toughest industrial environments

- 🚀 Limited stock! Ensure your safety today and avoid downtime

🎯 Act Now! Click below to secure the safest cable glands for your project BEFORE it’s too late:

👉 Get Explosion Proof Cable Glands

👉 See Industrial Cable Glands

👉 Explore Comprehensive Explosion Protection

The Various Types of Wires

1. Copper Wire

Copper types of wire may probably be the most familiar type used in many applications. This is so because it exhibits brilliant conductivity and flexibility. It finds broad usage in electrical cabling for residential, commercial, industrial, and other uses. The high conductivity exhibited by copper minimizes energy loss, making it appropriate for transmitting electricity over long distances efficiently.

2. Aluminum Wire

Another very common choice, especially on power distribution networks, is aluminum types of wire. Though not as conductive as copper, aluminum is much cheaper and has a lighter weight, which can be helpful in large installation scales. Proper installation procedures, however, are still necessary to overcome the inherent difficulties that may arise with the oxidizing tendency of aluminum.

3. Steel Wire

Major applications for steel types of wire are confined only to the structural areas where strength and durability become prime concerns. Extensive usage is found in the construction industry, more precisely in the reinforcement of concrete structures, fencing, and suspension bridges. This, then, becomes the base for steel wire applications under tension, reflecting its requirement in an environment that demands strong support and the aspect of longevity.

4. Nichrome Wire

Nichrome wire is self-setting because it is capable of withstanding high temperatures without oxidation, with an alloy percentage of nickel-chromium. It also allows itself in appliances like a toaster, oven, and industrial furnace, which require uniform and precise heat production.

5. Tinned Copper Wire

Tinned copper wire is copper wire with a thin layer of tin over it so as to enhance its capability of resisting corrosion. This type of wire is used in marine and automotive wiring and wherever exposure to moisture and oxidation is likely. Tinning also eases soldering, therefore giving an easy way to make reliable soldered joints.

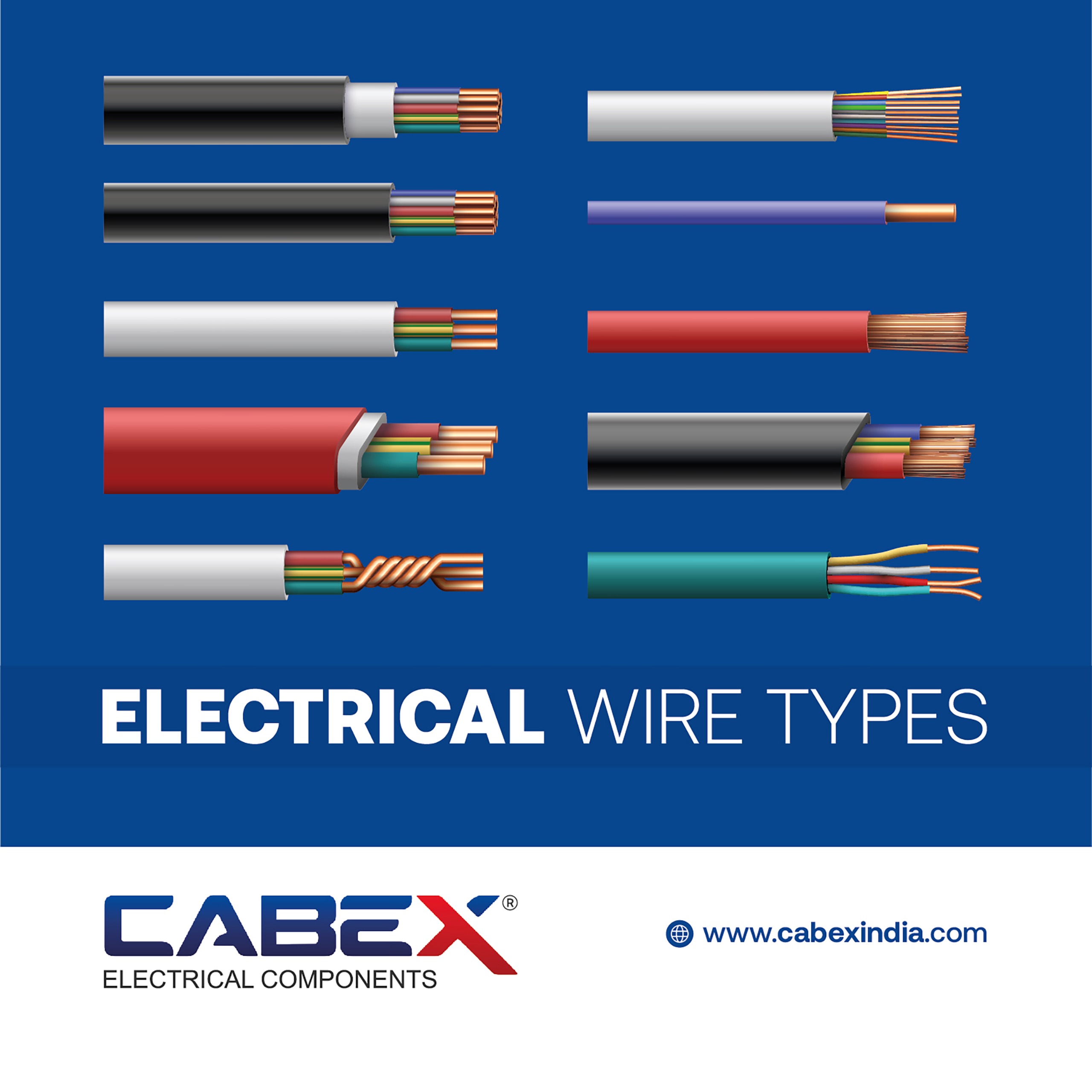

Here are some types of wire commonly used:

Solid wire: The kind of wire employed in applications where flexibility is not required, such as in-house electrical wiring.

Stranded wire: This kind of wire consists of many thin strands that have been twisted or even braided together, making it quite flexible and durable. This kind of wire is applied in various types of electronic devices and appliances.

Twisted pair: Consists of two insulated wires wound together. The role of this type of wire is to prevent electromagnetic interference. It is common in cords and network wires for telecommunications.

Coaxial cable: It has a central conductor wire with insulation, a braided wire shield, and an outer insulating layer. It is mainly used in cable television and computer networking.

Shielded wire: This is wire with an added layer of shielding, usually foil or braided wire, protecting the wires from electromagnetic interference; it is mainly used in sensitive electronic circuits.

Hook-up wire: It is a single insulated wire used in low-current and low-voltage works, like breadboarding and other electronic duties.

Ribbon cable: A flat cable with a multiple of conductors, side by side. This type of cable is applied with computers and peripheral devices where space is saved and organization is deemed important.

Barbed wire: A fencing wire that comes with sharp edges or points, used for security fencing.

Also read: Safe & Secure: Install a Lightning Arrester in Home

Applications of Various Types of Wire

Wiring of Buildings

Any building, commercial, industrial, or residential, prefers copper wire for its huge conductivity and proven safety record from starting time. It ensures a good flow of power without any risk of overheating and electrical fire. This particular case becomes highly appreciable especially with regard to the checking of building safety codes.

Power Transmission Networks

Across enormous power transmission networks, aluminum wire supports a larger stage in bringing electricity from generating stations to eventually distribution substations and then to homes and businesses, because of its lightweight and this reduces the cost of installations. allowing easier handling over long distances.

Industrial Applications

In industrial environments, steel wire is indispensable for reinforcing concrete structures, securing loads in shipping containers, or heavy-duty fencing. It possesses the strength and durability for very demanding applications where questions of safety and reliability are not allowed.

Heating Elements

Nichrome wire is an excellent choice for heating elements in heating appliances and industrial machinery. This is because it possesses a very high electric resistance when at high temperatures, coupled with an enormous, predictable function. Most of these heating system equipped with Ni-Cr wire achieve smooth running. Due to this predictable and consistent heat maintained, these devices give a very long span of life.

Special Environments

A tinned copper wire is therefore only found in few special environments, for instance in marine vessels and in automotive use for their wiring harnesses. Its intrinsic resistance to corrosion safeguards long-term service in harsh conditions where moisture and salt destroy their naked counterparts.

Considerations for Choosing the Right Type of Wire

Conductivity Requirements

While selecting wire for any application, its conductivity against the electrical load is always a primary consideration. Copper wire leads in all high-conductivity applications, and aluminum wire offers a lower-cost alternative where lower conductivity is not of major concern.

Environmental Conditions

Wire material selection is made depending on environmental conditions like moisture, temperature extremes, and chemical exposure. Tinned copper wire is used in corrosive environments, while Nichrome is used in high-temperature applications; this allows for assurance of its reliability and safety in the long term.

Regulatory Compliance

Local and international standards on electrical and construction materials are very imperative. The selection of wires that meet or are above the threshold of these standards leads to compliance with safety regulations and reduces risks related to substandard materials.

Causes and Risk Factors

- Environmental factor

- Mechanical Stress

- Corrosion & Oxidation

Oxidation Diagnosis and Tests

- Visual Inspect

- Electrical Testing Methods

Treatment Options

- Repair vs. Replacement

- Upgrading Wire Performance

Conclusion

Therefore, being informed on the various types of wires that are available today for application in electrical engineering, construction and industry generally gives one an upper hand. Various classes of wires provide specific characteristics that best suit various needs; from conductivity and durability to heat resistance and stopping corrosion. Proper selection of wire means that professionals can be sure of efficient performance, safety and compliance with industry standards.

📞 Need Help Choosing the Right Wire?

Get Expert Advice from Cabex »

Wire Types FAQs

What are three different types of electrical wire?

Copper, aluminum, and silver wire are used for electrical conductivity in some applications.

Explain the difference between single-conductor and multi-conductor electronic wire?

Single-conductor wire includes one insolated conductor while multi-conductor wire has many insolated conductors in one cable.

how for magnet wire where and how this is used?

Magnet wire is typically insulated using enamel. It is used to create the coils in highly compact structures for applications, such as transformers and motors.

How might environmental factors affect industrial wires?

Environmental factors specifically involve temperature changes, moisture and likely exposure to chemicals. Hence, the wires that are employed in an industrial environment should be high-temperature or armored cables.

Why are fiber optic communication cables better than the regular coaxial cables?

Fiber optic cables offer higher data transmission but higher bandwidth and immunity toward electromagnetic interference compared to coaxial cables.

How can I avoid wire degradation and ensure longevity?

I can prevent degradation and ensure longevity by correctly choosing the right wire and then using the proper method of installation.

What are some common signs of wire failure or deterioration?

These indications are insulation discoloration, the insulation is damaged, evident heating, and electrical issues like short circuits or voltage drop.

Why is it essential to match wire types to specific applications?

Specific type of wire will ensure high-safety and reliable operation and the best possible performance formany applications.

You May Also Like: Buy Flameproof Cable Glands Online – Best Deals & Prices in India , What Are the Hazards of Cable Glanding