Cable Gland are an essential component of any electrical system, providing a secure and reliable connection between cables and equipment. With so many different types of cable and gland available, selecting the right one for your application can be a daunting task. In this article, In this blog, we’ll guide you on How to Select Cable Gland?

Introduction to Cable Gland

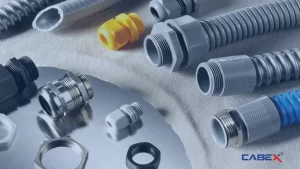

A cable gland, also known as a cable connector or electrical gland, is a device used to secure and seal the end of a cable where it enters a piece of equipment or enclosure. Cable and gland provide several benefits, including:

- Protection from environmental hazards such as dust, moisture, and debris

- Prevention of cable pullout

- Prevention of cable damage from vibration and impact

- Maintenance of cable integrity

- Prevention of electrical hazards

How to Select Cable and gland?

Here are following points to select cable gland:

1. Determine the Cable Size and Type

Before selecting a cable gland, you need to determine the size and type of the cable you’re working with. The cable size will determine the diameter of the cable gland you’ll need. Additionally, the type of cable you’re using can affect the type of gland you need, especially if you’re working with hazardous area cables. Some cable glands are designed specifically for use with armored cables, while others are suitable for non-armored cables.

2. Consider the Environment

Another important factor to consider when selecting a cable gland is the environment in which it will be used. If the cable is exposed to harsh weather conditions or other hazards, you’ll need a gland that can withstand these conditions. Additionally, if the cable is being used in a hazardous area, you’ll need a gland that’s designed to meet the relevant safety standards.

3. Choose the Right Material

Cable glands are made from various materials such as brass, stainless steel, aluminum, and plastic. The material you choose will depend on the application and the environment. For example, if the gland is being used in a corrosive environment, you’ll need a gland made from a corrosion-resistant material such as stainless steel.

4. Select the Type of Seal

The type of seal you choose will depend on the level of protection required. Cable and gland can have different types of seals, including compression seals, displacement seals, and compound seals. Compression seals are the most common type and are suitable for most applications. Displacement seals are used in applications where the cable may need to be removed and replaced frequently. Compound seals are used in applications where a high level of sealing is required.

5. Choose the Right Type of Electrical Gland

There are various types of electrical glands, including armored, non-armored, flameproof, and explosion-proof. Armored glands are suitable for use with armored cables, while non-armored glands are used with non-armored cables. Flameproof glands are designed to prevent the spread of flames in the event of a fire. Explosion-proof Cable and gland are designed to prevent sparks from igniting flammable gases or dust in hazardous areas.

Factors to Consider When Selecting Cable Glands

When selecting a cable gland, there are several factors to consider, including:

1. Cable type and size:

The type and size of the cable will determine the size and type of cable gland required. It is essential to select a gland that is compatible with the cable type and size.

2. Environmental conditions:

The environmental conditions where the gland will be installed, such as temperature, humidity, and corrosive elements, must be taken into account to ensure that the gland is suitable for the application.

3. Hazardous areas:

If the cable gland will be installed in a hazardous area, such as a location with flammable gases or liquids, it must be designed and certified for use in that environment.

4. IP rating:

The IP (Ingress Protection) rating of the cable gland indicates its level of protection against dust and moisture. The appropriate IP rating should be selected based on the environmental conditions where the gland will be installed.

5. Material:

Cable glands are available in a variety of materials, including brass, stainless steel, and plastic. The material should be selected based on the application requirements and the environmental conditions.

What is Cable Gland Types?

There are several types of cable glands available, including:

1. Compression cable glands:

These glands use a compression fitting to create a seal around the cable, providing a secure and watertight connection.

2. Threaded cable glands:

These glands use a threaded connection to secure the cable, making them ideal for applications where the cable needs to be frequently disconnected.

3. Barrier cable glands:

These glands provide additional protection against fire, explosion, and other hazards by creating a barrier around the cable.

4. Explosion-proof cable glands:

These glands are designed for use in hazardous areas and are certified for use in explosive atmospheres.

Installation Tips for Cable Glands

When installing cable glands, there are several tips to keep in mind to ensure a secure and reliable connection, including:

- Use the correct size gland for the cable to ensure a secure fit.

- Clean and dry the cable and gland before installation to prevent contamination and ensure a good seal.

- Use a sealing compound or tape to create a watertight seal around the cable.

- Follow the manufacturer’s instructions for installation, torque values, and environmental conditions.

How Do You Calculate Cable size?

Calculating the correct cable size is important to ensure that the cable can carry the required electrical load safely and efficiently. Here are the steps to calculate the cable size:

1. Determine the load:

The first step is to determine the electrical load that the cable will be carrying. This can be calculated in watts (W), kilowatts (kW), or amperes (A). You can find this information on the equipment or device that the cable will be connected to.

2. Determine the voltage:

Next, determine the voltage of the circuit. This can also be found on the equipment or device or in the circuit diagram.

3. Determine the length of the cable run:

The length of the cable run from the power source to the device must be measured.

4. Determine the allowable voltage drop:

The allowable voltage drop is the maximum voltage drop that is allowed for the circuit. This is typically 3% for low voltage circuits and 5% for high voltage circuits.

5. Calculate the cross-sectional area:

Using the information gathered in steps 1-4, the cross-sectional area of the cable can be calculated using a cable sizing calculator or by referring to cable sizing tables provided by cable manufacturers. The cross-sectional area of the cable is expressed in square millimeters (mm²) or square inches (in²).

6. Check the ampacity:

Once the cross-sectional area of the cable has been calculated, check the ampacity rating of the cable. The ampacity rating is the maximum current that the cable can safely carry without overheating.

7. Choose the appropriate cable size:

Choose the cable size that has the appropriate ampacity rating and is available in the required length.

It is important to note that cable sizing can be complex and it is recommended to consult with a qualified electrician or engineer if you have any doubts or questions about calculating the cable size for your application.

Which Cable is Suitable for M20 Gland?

The size of the cable gland required depends on the diameter of the cable that will be passed through it. For an M20 cable gland, a cable with a diameter between 6mm to 12mm is typically used.

Some commonly used cables with a diameter within this range are:

- 1.5mm² 2-core and 3-core cables

- 2.5mm² 2-core and 3-core cables

- 4mm² 2-core and 3-core cables

- 6mm² 2-core and 3-core cables

It’s important to note that the exact cable size will depend on the specific application and the electrical load that will be carried by the cable. It is recommended to consult with a qualified electrician or engineer to determine the appropriate cable size and type for your specific application.

Conclusion: How to Select Cable Gland?

In conclusion, selecting the right cable gland is essential for ensuring a secure and reliable connection between Cable and gland equipment. By considering the factors discussed in this article, such as cable type and size, environmental conditions, and hazardous area requirements, you can select the appropriate cable gland for your application.

Read Also: What Is the Difference Between Bw and Cw Cable Glands

Read Also: What is Double Compression Cable Gland

A1 and A2 are types of cable glands used for securing and protecting cables. A1 is for unarmoured cables, while A2 is for armoured cables.

M32 cable gland is a type of cable entry device used to attach and secure electrical cables to equipment. It has a 32mm diameter and is commonly made of plastic or metal.

M25 cable gland size refers to a metric thread size commonly used for cable glands, with an outer diameter of approximately 25mm.

A 50 mm cable gland size is typically used for cables with an outer diameter between 34-42 mm. The gland itself may be larger due to threading and other features.

High tension (HT) cables are typically made of insulated copper or aluminum conductors and are used to transmit high voltage electrical power.