Introduction

Cable joints are essential in the field of electrical engineering and power distribution. These vital parts act as connectors, allowing power to move across wires smoothly and efficiently while preserving safety. Ensuring dependable electrical systems requires an understanding of cable joint types, installation procedures, and maintenance requirements.

Types and Categories of cable joints

Cable joints that heat shrink

– A description of the process behind heat shrinking

– Benefits and usage scenarios

– A detailed installation procedure

– Industries that frequently use heat shrink joints

Cold Shrink Cable Joints:

– The ways in which heat shrink and cold shrink joints are different

– Advantages and restrictions

– Methods of installation

– Adequate conditions for cold shrink joints

Resin Cable Joints

– Benefits under challenging conditions.

– Installation concerns.

– Resin joint maintenance requirements.

Mechanical Cable Joints

– An introduction to mechanical connectors

– Appropriate uses.

– Tools and installation procedures.

– Reliability and durability in comparison to other kinds.

Symptoms and Signs

Faulty Connections

– Signs of loose or damaged joints.

– Effects on electrical performance.

– Safety hazards associated with faulty connections.

Heat Build-Up

– Recognizing excessive heat at joint locations.

– Potential causes and implications.

– Importance of addressing heat-related issues promptly.

Insulation Damage

– Indications of insulation degradation.

– Impact on cable integrity.

– Risks of electrical shorts and arcing.

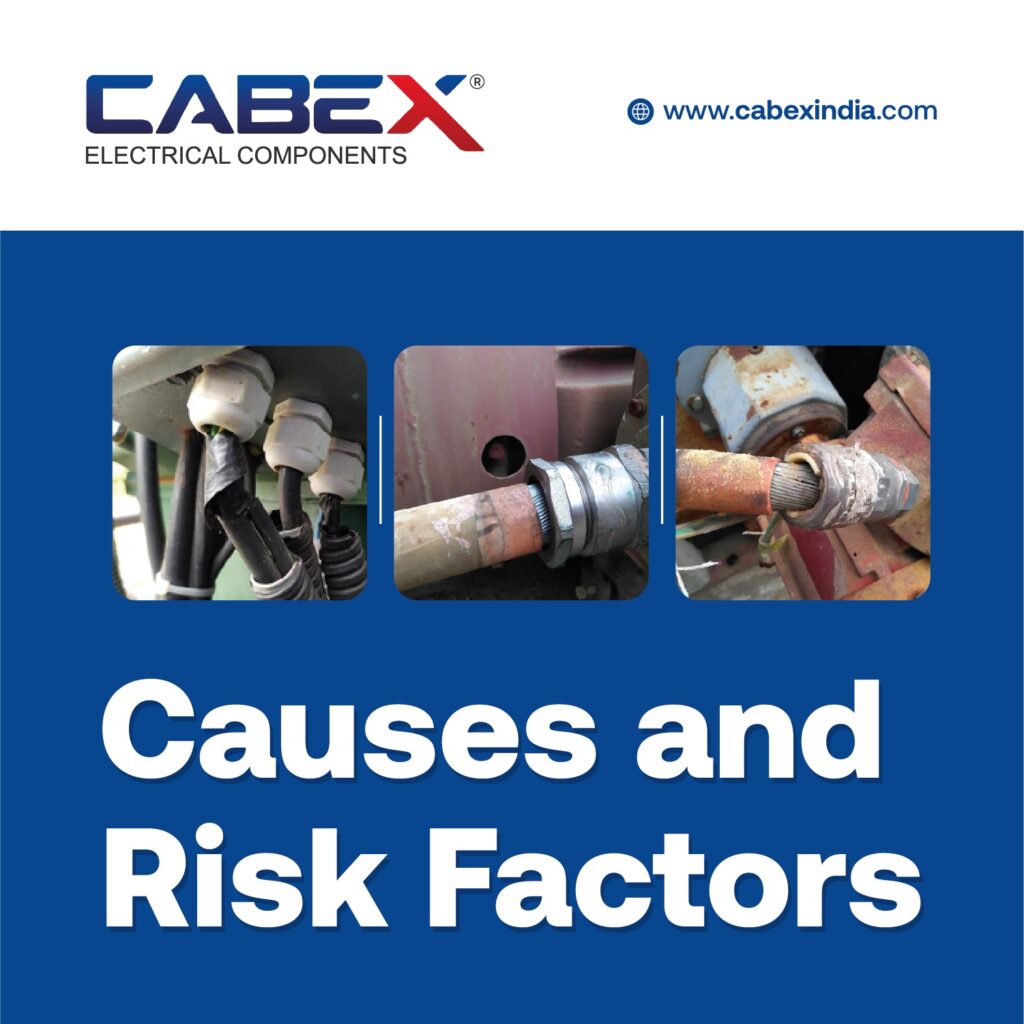

Causes and Risk Factors

Poor Installation Practices

– Importance of proper joint preparation.

– Common mistakes during installation.

– Effects on long-term performance and safety.

Environmental Factors

– Influence of temperature fluctuations.

– Exposure to moisture and contaminants.

– Strategies for mitigating environmental risks.

Overloading and Overheating

– Consequences of exceeding cable capacity.

– Effects on joint integrity and lifespan.

– Importance of load monitoring and management.

Diagnosis and Tests

Visual Inspection

– Importance of routine visual checks.

– What to look for during inspections.

– Recommended inspection intervals.

Electrical Testing

– Overview of continuity and insulation resistance tests.

– Equipment required for testing.

– Interpretation of test results.

Treatment Options

Repair vs. Replacement

– Factors influencing repair decisions.

– When replacement is necessary.

– Steps involved in repairing cable joints.

Upgrading Technologies

– Advantages of upgrading to modern joint solutions.

– Considerations for retrofitting existing systems.

– Cost-benefit analysis of upgrades.

Preventive Measures

Proper Installation Procedures

– Importance of following manufacturer guidelines.

– Training requirements for installers.

– Certification programs for cable joint technicians.

Regular Maintenance Schedule

– Developing a maintenance plan for cable joints.

– Frequency of inspections and testing.

– Documentation and record-keeping best practices.

Personal Stories or Case Studies

Case Study: Industrial Facility

– Narrative detailing the impact of cable joint failures.

– Lessons learned and preventive measures implemented.

– Testimonials from maintenance personnel.

Expert Insights

Industry Expert Interview

– Interview with a seasoned electrical engineer.

– Insights into common challenges and best practices.

– Recommendations for optimizing cable joint performance.

Conclusion

In conclusion, cable joints are indispensable components in electrical systems, facilitating the seamless transmission of power while ensuring safety and reliability. By understanding the various types, installation methods, and maintenance requirements, engineers and technicians can mitigate risks and enhance the longevity of electrical infrastructure.