Industrial Cable Glands

Introduction

When it comes to electrical installations, ensuring safety, reliability, and longevity is paramount. One integral component that often goes unnoticed but plays a crucial role in safeguarding electrical systems is the industrial cable gland. In this comprehensive guide, we delve into everything you need to know about these essential fittings, from their function to their installation and maintenance.

What are industrial cable glands?

Industrial cable glands, also known as cable connectors or cable fittings, are mechanical devices used to secure and protect electrical cables where they enter electrical equipment, junction boxes, or enclosures. These glands provide strain relief, prevent cable pullout, and offer environmental protection, ensuring the integrity of the electrical installation.

Importance of industrial cable glands

The significance of industrial cable glands lies in their ability to maintain the safety and functionality of electrical systems. By securely fastening cables and sealing out environmental elements such as dust, moisture, and chemicals, cable glands minimize the risk of electrical hazards, equipment damage, and downtime.

Types of industrial cable glands

When it comes to electrical installations, ensuring safety, reliability, and longevity is paramount. One integral component that often goes unnoticed but plays a crucial role in safeguarding electrical systems is the industrial cable gland. In this comprehensive guide, we delve into everything you need to know about these essential fittings, from their function to their installation and maintenance.

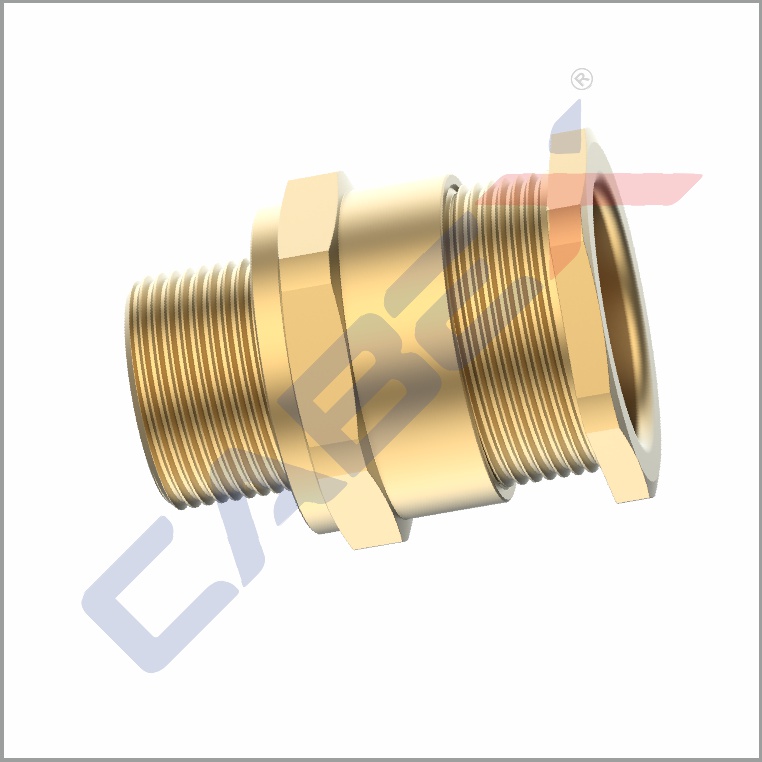

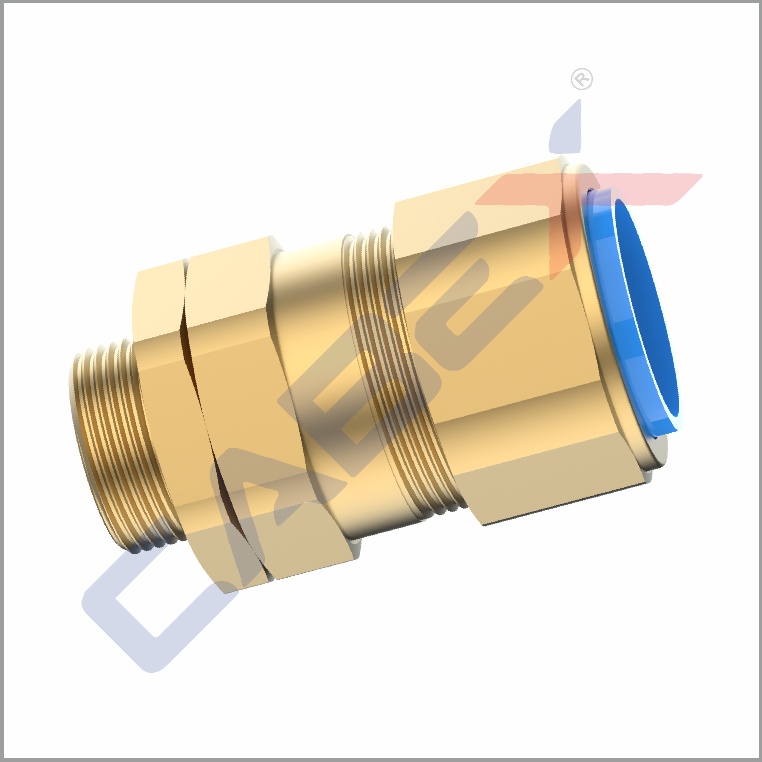

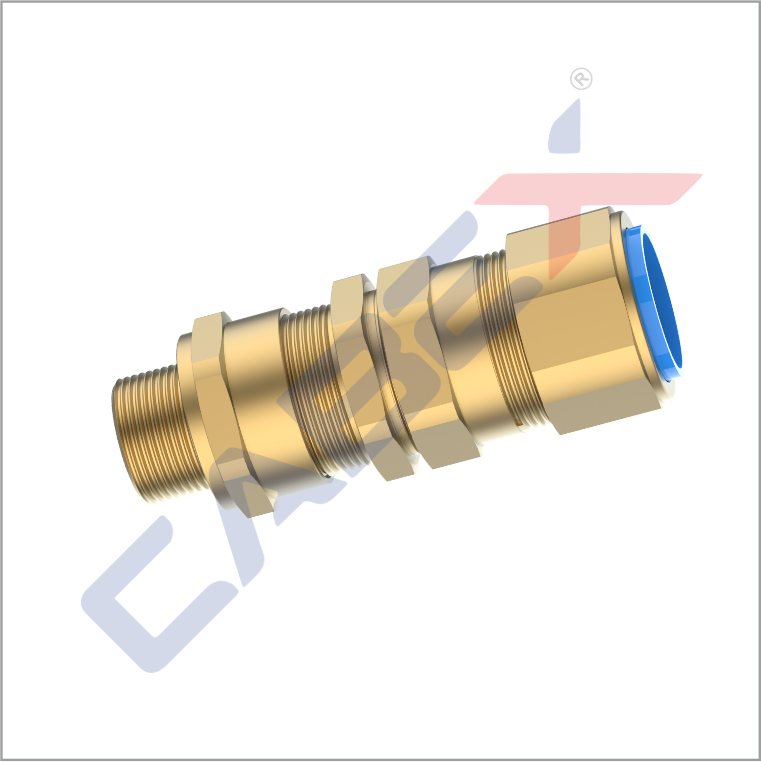

Armored Cable Glands

Armored cable glands, also known as cable glands for SWA (Steel Wire Armored) cables, feature robust construction to accommodate cables with metallic armor. These glands provide enhanced mechanical protection and are suitable for demanding industrial settings.

Non-armored Cable Glands

Non-armored cable glands are designed for use with cables that do not have metallic armor. They are ideal for applications where mechanical protection is not a primary concern but environmental sealing is essential.

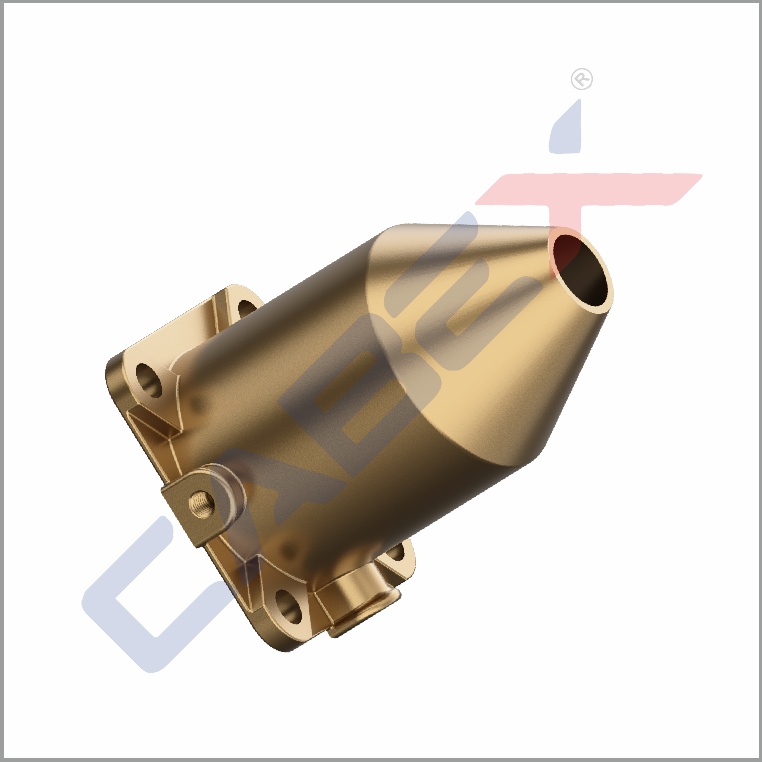

Explosion-proof Cable Glands

Explosion-proof cable glands are specially engineered to prevent the propagation of explosions from hazardous areas to safe zones. These glands feature flameproof enclosures and are commonly used in petrochemical plants, oil refineries, and other volatile environments.

Waterproof Cable Glands

Waterproof cable glands, as the name suggests, are designed to prevent the ingress of water and moisture into electrical enclosures. They feature a watertight seal and are suitable for outdoor installations or areas prone to exposure to liquids.

EMC Cable Glands

EMC (Electromagnetic Compatibility) cable glands are used in applications where electromagnetic interference (EMI) and radiofrequency interference (RFI) need to be mitigated. These glands provide effective shielding to prevent signal distortion and maintain signal integrity.

Understanding Industrial Cable Glands

Industrial cable glands typically consist of several components, including a gland body, sealing mechanism, sealing ring, locknut, and compression nut. Each component plays a vital role in ensuring the proper installation and sealing of the cable gland.

How industrial cable glands work?

Industrial cable glands work by providing a secure and watertight seal around the cable entry point of an electrical enclosure. The gland compresses the sealing ring against the cable, forming a tight seal that prevents the ingress of moisture, dust, and other contaminants.

Applications of industrial cable glands

Industrial cable glands find applications across various industries, including manufacturing, construction, oil and gas, telecommunications, and renewable energy. They are used in electrical panels, control cabinets, machinery, instrumentation, and outdoor installations to ensure reliable cable management and protection.

How to Choose the Right Cable Gland

Environmental considerations

When selecting a cable gland, it’s essential to consider the environmental conditions in which it will be installed. Factors such as temperature extremes, exposure to chemicals, UV radiation, and outdoor elements should influence the choice of gland material and sealing properties.

Cable material compatibility

Different types of cables require specific gland materials to ensure compatibility and longevity. Whether dealing with PVC, rubber, armored, or non-armored cables, it’s crucial to select a cable gland that is compatible with the cable material to prevent degradation and ensure a secure connection.

Size and thread type

Choosing the correct size and thread type of the cable gland is essential to ensure a proper fit and seal. Glands are available in various sizes and thread standards, including metric, PG, and NPT. Matching the gland size to the cable diameter and selecting the appropriate thread type for the installation surface is crucial for optimal performance.

Installation requirements

Consideration should be given to the installation process and any specific requirements or standards that need to be followed. Proper gland installation involves cable preparation, gland assembly, tightening of compression and locking nuts, and verification of the seal integrity. Adhering to installation guidelines is critical for safety and compliance.

Installing Industrial Cable Glands

Preparation

Before installing a cable gland, ensure that the cable and gland components are clean and free from debris. Verify the compatibility of the cable and gland materials, and make any necessary adjustments to accommodate the cable diameter and construction.

Step-by-step installation process

Prepare the cable: Strip the cable jacket to expose the conductors and ensure proper length for termination.

Assemble the gland: Insert the cable through the gland body, ensuring that the sealing ring is positioned correctly.

Tighten the compression nut: Securely tighten the compression nut to compress the sealing ring against the cable, forming a watertight seal.

Secure the gland: Use the locknut to secure the gland to the enclosure or mounting surface, ensuring a stable and secure connection.

Common installation mistakes and how to avoid them

Over-tightening: Excessive tightening of the compression nut can damage the cable or compromise the seal. Follow manufacturer recommendations for torque values.

Incorrect cable preparation: Improper cable stripping or preparation can affect the integrity of the connection. Use appropriate tools and techniques for cable preparation.

Using incompatible materials: Using mismatched gland and cable materials can lead to corrosion or degradation over time. Ensure compatibility between materials to avoid issues.

Maintenance and Troubleshooting

Regular maintenance

Performing regular inspections and maintenance of cable glands is essential to ensure continued functionality and reliability. Inspect glands for signs of damage, corrosion, or wear, and replace any components as needed. Clean glands and surrounding areas to remove dirt, debris, or contaminants that could compromise the seal.

Troubleshooting common issues

Leaking glands: Leaks can occur due to improper installation, damaged components, or environmental factors. Inspect glands for signs of leakage and address any issues promptly.

Cable pullout: Inadequate strain relief or improper cable termination can result in cable pullout. Ensure that cables are securely fastened and strain relieved to prevent accidental disconnection.

Corrosion: Exposure to corrosive environments can lead to corrosion of gland components. Use corrosion-resistant materials and perform regular inspections to identify and address corrosion issues.

When to replace cable glands?

Cable glands should be replaced if they show signs of damage, wear, or degradation that could compromise their performance. Additionally, glands should be replaced if they no longer provide a secure seal or strain relief for the cables.

Safety Considerations

Electrical safety

Proper installation and maintenance of cable glands are essential for electrical safety. Ensure that glands are installed correctly, and cables are properly terminated to prevent electrical hazards such as short circuits or shocks.

Environmental protection

Industrial cable glands play a vital role in protecting electrical equipment from environmental hazards such as dust, moisture, and chemicals. Selecting the appropriate gland and ensuring a proper seal are essential for maintaining environmental protection.

Hazardous location considerations

In hazardous environments where the risk of explosion or fire is present, explosion-proof cable glands are necessary to prevent the spread of ignition sources. Ensure that glands used in hazardous locations comply with relevant safety standards and regulations.

Compliance with industry standards and regulations

When selecting and installing cable glands, it’s essential to adhere to industry standards and regulations to ensure safety and compliance. Familiarize yourself with applicable standards such as IEC, NEC, and ATEX, and follow best practices for cable gland selection, installation, and maintenance.

Conclusion

Industrial cable glands are indispensable components in electrical installations, providing essential functions such as cable management, strain relief, and environmental protection. By understanding the different types of cable glands, their installation requirements, and maintenance considerations, you can ensure the safety, reliability, and longevity of your electrical systems.

Whether you’re designing a new electrical installation or upgrading an existing one, selecting the right cable glands and following best practices for installation and maintenance are critical. By prioritizing safety, compliance, and performance, you can maximize the efficiency and effectiveness of your electrical systems while minimizing risks and downtime.