Manufacturing Facilities:

Currently, we are operating through our 25,000 sq- ft. modern equipped facility, having a state-of-the-art right from the Forging operation, Single Spindle Automated Machines, CNC Machines, Laser Marking Machines & more than 100 medium to large size Machines backed by experienced & technical expert staff.

Raw Material:

Our storage facility is maintained in such a manner to manage even emergency orders smoothly & maintain the quality of raw materials and finished goods to minimize manufacturing time & speed up delivery. We have the facility to store a wide range of raw materials such as Brass Rods (Grade: CuZn39Pb2 & CuZn39Pb3), Stainless Steel (SS 316 & 316 L), Aluminum Electrical Grade, Copper 99.9%, Rubber parts of EPDM & Silicone,Engineering Plastic Nylon 66 & PPS etc…

Forging:

Our forging plant capacity is 100 Metric Ton per month to obtain products of exemplary quality.

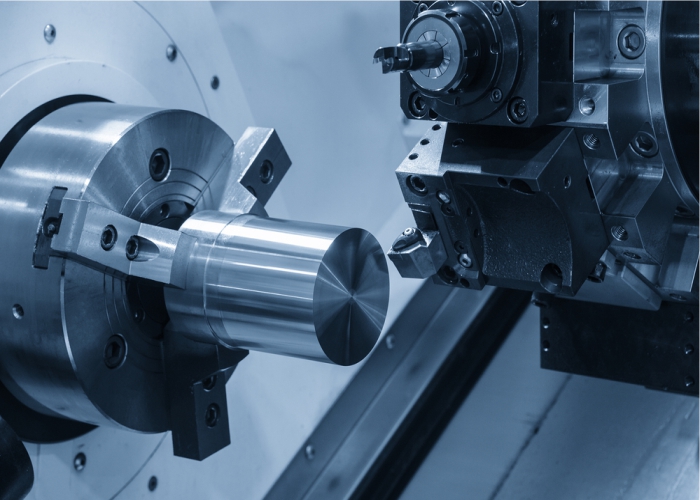

Machining:

Our fully-equipped machining facility at Cabex enables us to collaborate with several clients across an array of industries.

We believe that no project is too small or too big for us, right from confirmation of order to delivery our agenda is to fulfill the requirements of our clients. For that, we constantly evolve our practices and upgrade software and machines on the shop floor to ensure that the machines can handle and operate even at high tolerance and speed to meet the project’s demand.

Our shop floor consists of CNC, VMC, Traub machines, etc.

Plating:

We acknowledge the importance of plating in inhibiting corrosion, changing conductibility, improving wear, boosting solderability, reducing friction, heat resistance and hardening the material. Our plating process aims at improving the performance of the material which modifies its application in precision machining.

We provide an extensive range of plating including Electro Plating, Electroless Plating,Nickel Plating, Chrome Plating, Copper Plating, etc…,as per the project requirements.

QC & Testing:

We have Calibrated Instruments in the QC Department for the seamless & smooth quality and inspection process. Our standard quality testing protocol mandates inspection before the materials, components, finished products are assembled, dispatched, and used.

We perform 3 stages of quality testing by our team of experts headed by the quality inspector:

- Incoming Quality Check of raw materials.

- Inprocess Quality Check of the machining process.

- Final Quality Check of finished & assembled products exclusively using NABL-approved and calibrated instruments and in accordance with an approved sampling plan.

Packaging & Shipping:

We aim to transform the process from buying to shipping into a world-class experience for our customers. We ship our products in corrugated boxes, palletized with proper labeling and marking as per the customer’s requirement.

We ship our products from Kandla port, Mundra port, Nhava Sheva port, Ahmedabad airport, and Mumbai airport, enabling us to ship and export worldwide.