EX CABLE GLANDS

There are various types of Cable Glands & Accessories manufactured around the world as per different standards and applications.

We CABEX manufacturing different Ex Cable Gland & Accessories as per below:

Available in multiple dimensions, thread forms and materials; CABEX Cable Glands conform to the latest international standards — including BS EN 62444, IEC 62444 and the more rigorous BS 6121:Part 1:1989.

EX CABLE GLANDS

| Type | Application |

|---|---|

| A2F | Certified in Flamproof (Type 'db'), Increased Safety (Type 'eb') & Dust Ignition protection (Type 'ta') for Indoor & Outdoor use in Zone 1,2,20,21 & 22 hazardous areas with Unarmoured & Braided Cable providing a combined Flameproof Seal & an Environmental Seal on the cable Outer Sheath. This Cable Gland for Group || & |||. |

| CFU | Certified in Increased Safety (Type 'eb') & Dust Ignition protection (Type 'ta') for Indoor & Outdoor use in Zone 1,2,20,21 & 22 hazardous areas with all types of Armoured Cable providing an Environmental Seal on the cable Outer Sheath. Also providing Mechanical Cable Retention & an Electrical Continuity via armour wire termination. This Cable Gland for Group |, || & |||. |

E1FU |

Certified in Flamproof (Type 'db'), Increased Safety (Type 'eb') & Dust Ignition protection (Type 'ta') for Indoor & Outdoor use in Zone 1,2,20,21 & 22 hazardous areas with all Armour Cable providing a combined Flameproof Seal & an Environmental Seal on the cable Inner Bedding & Outer Sheath. Also providing Mechanical Cable Retention & an Electrical Continuity via armour wire termination. This Cable Gland for Group |, || & |||. |

A2F-HT |

Certified in Flamproof (Type 'db'), Increased Safety (Type 'eb') & Dust Ignition protection (Type 'ta') for Indoor & Outdoor use in Zone 1,2,20,21 & 22 hazardous areas with Unarmoured & Braided Cable providing a combined Flameproof Seal & an Environmental Seal on the cable Outer Sheath. This Cable Gland for Group || & |||.This is a High Temperature Cable Gland. |

CFU-HT |

Certified in Increased Safety (Type 'eb') & Dust Ignition protection (Type 'ta') for Indoor & Outdoor use in Zone 1,2,20,21& 22 hazardous areas with all types of Armoured Cable providing an Environmental Seal on the cable Outer Sheath. Also providing Mechanical Cable Retention & an Electrical Continuity via armour wire termination. This Cable Gland for Group |, || & |||.This is a High Temperature Cable Gland. |

E1FU-HT |

Certified in Flamproof (Type 'db'), Increased Safety (Type 'eb') & Dust Ignition protection (Type 'ta') for Indoor & Outdoor use in Zone 1,2,20,21 & 22 hazardous areas with all Armour Cable providing a combined Flameproof Seal & an Environmental Seal on the cable Inner Bedding & Outer Sheath. Also providing Mechanical Cable Retention & an Electrical Continuity via armour wire termination. This Cable Gland for Group |, || & |||.This is a High Temperature Cable Gland. |

EX THREAD CONVERSION & BLANKING PLUG

| Type | Application |

|---|---|

| Ex ADAPTOR | Change smaller thread to larger thread when there is a disconnect between the type or size of the Cable Gland thread and the cable entry hole in the equipment. |

| Ex REDUCER | Change larger thread to smaller thread when there is a disconnect between the type or size of the Cable Gland thread and the cable entry hole in the equipment. |

Ex STOPPING PLUG

|

To close unused Cable Gland entries temporary or permanently & maintain the intergrity of the equipments. |

GENERAL ACCESSORIES

| Type | Application |

|---|---|

| EARTH TAG | Earth Tags are installed between the cable gland and equipment to provide earth bond connection. |

| LOCK NUT | Lock nuts are used for securing cable glands in position, and are used on the cable gland entry thread. |

| SERRATED WASHER | Fitted inside the equipment before Locknut as anti vibration device to prevent loosening the Cable Gland from the equipment. |

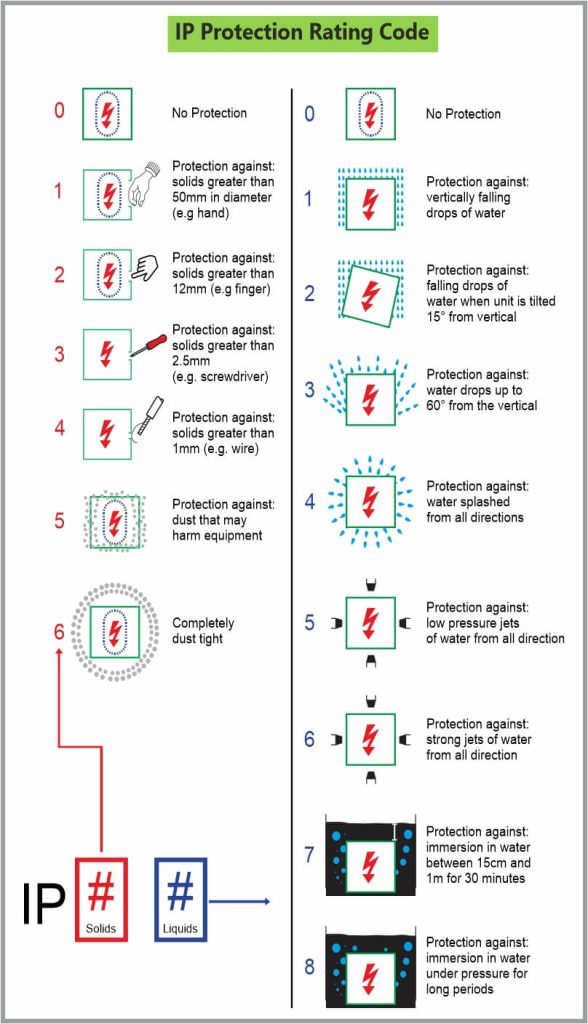

| NYLON & FIBER WASHER | Fit at entry thread at entrance of Cable Gland to equipment to maintain the Ingress Protection Rating and Code of Protection. |

| SHROUD | Keeping the surface of the Cable Gland free from the build-up of dust or dirt and retain unwanted moisture. |

MATRIX OF EX CABLE GLANDS

| Cable Gland Type |

Unarmoured Cables | Armoured Cables | Sealing Technique | Ingress Protection | High Temperature Option | Enclosure Protection | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Normal | SWA** | PWA | STA | Wire Braid | Strip | No Seal | Inner Seal | Outer Seal | IP 66 | IP 68* | Up to 175oC | Ex d | Ex e | Ex t | |

| A2F |  |

|

|

|

|

|

|

||||||||

| CFU |  |

|

|

|

|

|

|

|

|

|

|||||

| E1FU |  |

|

|

|

|

|

|

|

|

|

|

|

|||

| A2F-HT |  |

|

|

|

|

|

|

|

|||||||

| CFU-HT |  |

|

|

|

|

|

|

|

|

|

|

||||

| E1FU-HT |  |

|

|

|

|

|

|

|

|

|

|

|

|

||

| SWA | Single Wire Armour |  |

STANDARD | |

|---|---|---|---|---|

| PWA | Piliable Wire Armour | |||

| STA | Steel Tape Armour |

* IP 68 ratings are qualified with depth of water and duration of test. Please refer to individual product pages.

** SWA includes both Steel Wire Armour and Aluminium Wire Armour.

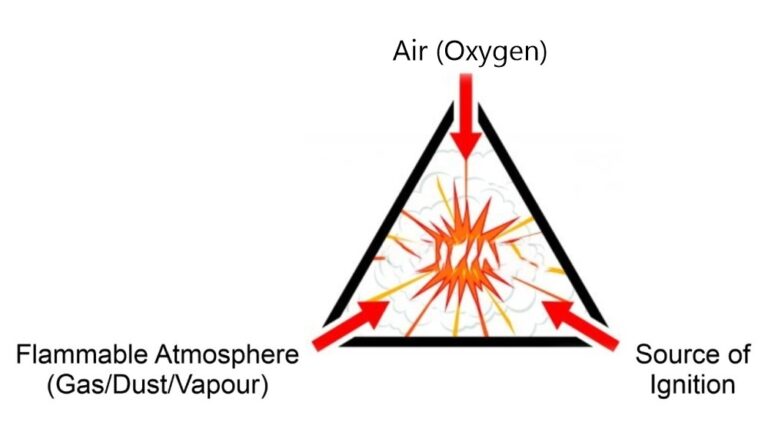

INTRODUCTION OF HAZARDOUS AREA

An area in which an explosive atmosphere is present, or may be expected to be present in quantities such as to require special precautions for the construction, installation and use of electrical apparatus.

In order to protect personal and equipment from potential explosions the principle of hazardous area classification is used this involves risk assessing the plant area and defining areas according to the type of flammable material and the probability of its release to create an explosive atmosphere.

DEFINITION OF “EXPLOSIVE ATMOSPHERE”

Mixture with air, under atmospheric conditions, of flammable substances in the form of gas, vapour, dust, fibres or flyings which, after ignition, permits a self-sustaining propagation.

STANDARD ATMOSPHERIC CONDITION

(according to IEC 60079-0)

- Temperature –20 °C to +60 °C

- Pressure 80 kPa (0.8 bar) to 110 kPa (1.1 bar)

- Air with normal oxygen content, generally 21% / vol.

CLASSIFICATION OF HAZARDOUS AREAS

(according to IEC 60079-10)

The hazardous areas are sub-divided into Zones:

Combustible Gases & Vapours

Area in which an explosive atmosphere consisting of a mixture of air with flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.

Area in which an explosive atmosphere consisting of a mixture of air with flammable substances in the form of gas, vapour or mist is likely to occur in normal operation or occasionally.

Area in which an explosive atmosphere consisting of a mixture of air with flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, persists for a short period only.

Combustible Dust & Fibres

Area in which an explosive atmosphere consisting of a mixture of air with flammable substances in the form of a cloud of combustible dust is present continuously, or for long periods or frequently.

Area in which an explosive atmosphere consisting of a mixture of air with flammable substances in the form of a cloud of combustible dust is likely to occur occasionally in normal operation.

Area in which an explosive atmosphere consisting of a mixture of air with flammable substances in the form of a cloud of combustible dust is not likely to occur in normal operation, but if it does occur, persists for a short period only.

NOTE: Above Figures A and B are an example only and must not be used as a model for an actual plant.

HAZARDOUS AREA EQUIPMENT

| Electrical Equipment | Symbol | Basic Concept of protection |

|---|---|---|

| Flameproof | d | Contain the explosion, quench the flame |

| Increased Safety | e | No arcs,sparks or hot surfaces |

| Dustproof Enclosure | t | Standard protection for dust, rugged tight enclosure |

ELECTRICAL EQUIPMENT IS DIVIDED INTO THREE GROUPS

Equipment intended for use in mines susceptible to firedamp (flammable mixture of gases naturally occurring in a mine).

Equipment intended for use in places with an explosive gas atmosphere other than mines susceptible to firedamp.

Group II equipment is subdivided into three subgroups

Atmospheres containing propane, or gases and vapours of equivalent hazard.

Atmospheres containing ethylene, or gases and vapours of equivalent hazard.

Atmospheres containing acetylene or hydrogen, or gases and vapors of equivalent hazard.

Equipment intended for use in places with an explosive dust atmosphere.

Atmospheres containing combustible flying.

Atmospheres containing non-conductive dust.

Atmospheres containing conductive dust.

ELECTRICAL EQUIPMENT PROTECTION CONCEPT EX d, EX e, EX t

- Flameproof Enclosure “d”

Enclosure in which the parts which can ignite an explosive gas atmosphere are placed and which can withstand the pressure developed during an internal explosion of an explosive mixture, and which prevents the transmission of the explosion to the explosive gas atmosphere surrounding the enclosure.

Level of Protection (EPL – Equipment Protection Level)

> Electrical equipment with flameproof enclosure “d” shall be one of the following:

Level of protection “da” (EPL “Ma” or “Ga”);

Level of protection “db” (EPL “Mb” or “Gb”); or

Level of protection “dc” (EPL “Gc”).

2. Increased Safety ”e”

Type of protection applied to electrical equipment or Ex Components in which additional measures are applied so as to give increased security against the possibility of excessive temperatures and against the occurrence of arcs and sparks.

- Level of Protection (EPL – Equipment Protection Level)

> Electrical equipment with increased safety “e” shall be one of the following:

Level of Protection “eb” (EPL “Mb” or “Gb”); or

Level of Protection “ec” (EPL “Gc”).

3. Dust Ignition Protection by Enclosure “t”

Type of protection for explosive dust atmospheres where electrical equipment is provided with an enclosure providing dust ingress protection and a means to limit surface temperatures.

- Level of Protection (EPL – Equipment Protection Level)

> Electrical equipment with dust ignition protection by enclosure “t” shall be either:

Level of Protection “ta” (EPL “Da”), or

Level of Protection “tb” (EPL “Db”), or

Level of Protection “tc” (EPL “Dc”).

CLASSIFICATION OF MARKING OF HAZARDOUS AREA |

|||||||||

| Flammable Material |

Hazardous Area |

Equipment Group as per directive 2014/34/EU (ATEX) |

Equipment Category as per directive 2014/34/EU (ATEX) |

Equipment Group as defined in EN/IEC 60079-0 |

Equipment Protection Level (EPL)as defined in EN 60079-0 |

||||

|---|---|---|---|---|---|---|---|---|---|

Methane |

NA |

I | M1 | I | Ma | ||||

| I | M2 | I | Mb | ||||||

Gas, Mist, Vapour |

Zone 0 | II | 1G | II | Ga | ||||

| Zone 1 | II | 2G | II | Gb | |||||

| Zone 2 | II | 3G | II | Gc | |||||

Dust |

Zone 20 | II | 1D | III | Da | ||||

| Zone 21 | II | 2D | III | Db | |||||

| Zone 22 | II | 3D | III | Dc | |||||

SUB DIVISION OF DUST |

SUB DIVISION OF GAS GROUP |

|||

| Group | Dust | Example | ||

|---|---|---|---|---|

| IIIA | Combustible Flyings | Fiber | IIA | |

| IIIB | Non-conductive Dust | Milk Powder | IIB | |

| IIIC | Conductive Dust | Graphite Powder | IIC | |

PROTECTION |

|||||

| Type of Protection | Symbol | Code | Zone | Norm | |

|---|---|---|---|---|---|

Flameproof Enclosure |

|

Exd | da | 0,1,2 | EN 60079-1 |

| db | 1,2 | ||||

| dc | 2 | ||||

Increased Safety |

|

Exe | eb | 1,2 | EN 60079-7 |

| ec | 2 | ||||

| ec | 2 | ||||

Dustproof Enclosure |

|

Ext | ta | 20,21,22 | EN 60079-31 |

| tb | 21,22 | ||||

| tc | 22 | ||||

Temperature Classes on Equipment |

|

| T Class | Surface Temperature |

|---|---|

| T1 | 450oC |

| T2 | 300oC |

| T3 | 200oC |

| T4 | 135oC |

| T5 | 100oC |

| T6 | 85oC |

|

E.g. When a site is classified as Zone 2/ II A/ T3 means Hot surfaces becomes dangerous ≥ 200°C & for that reason all Ex equipment shall be selected having a T class T3, T4, T5 or T6. |

|

Use of the Operating Equipment |

|

| Marking | Condition |

|---|---|

| Operating equipment can be used without restriction | |

| Special Condition of Use | |

| ∪ | Ex component, which is not intended to be used alone & requires additional certification. CE-confirmity is declared by the manfacturer if the part is fitted into a complete device |