Cable Damage in Hazardous Environments is one of the significant safety and operation risk factors. Effective strategies are necessary to be adopted in order to ensure that cables are properly serviced with much longevity and reliability in hazardous environments. Cable damage, electrical failure, fires, and improper system functioning lead to significant financial and operational setbacks. Therefore, understanding what causes cable damage in hazardous environments and working on preventive measures are very important to keep the working environment safe and efficient.

Understanding the Causes of Cable Damage in Hazardous Environments

Damage to cables in dangerous environments can result from mechanical, environmental, or electrical factors. First, a cause must be found before preventing damage. Cables are subjected to extreme conditions due to extreme working conditions associated with mining, oil and gas, and manufacturing industries. Knowing these risks allows for the implementation of proper safeguard measures to keep them from crashing after unplanned failure.

Common Causes of Cable Damage in Hazardous Environments

Multiple factors may lead to cable damage in hazardous environments, often causing operational failures and safety risks. Understanding these causes helps in taking the proper preventive measures.

1. Mechanical Stress

Abrasion, pinching, and bending beyond specifications compromise the integrity of a cable. Cable damage occurs with frequent high-frequency movement or pressure on it. Weakness of structure due to poor handling during installation or maintenance may cause the cable to fail soon.

2. Environmental Factors

Moisture, intense temperatures, and corrosive materials will degrade the cables. A high-humidity environment will break down the insulation. Temperature may make cables brittle or very flexible. Industrial chemical exposure will erode the protective coatings on the cables, which exposes them to further degradation.

3. Electrical Problems

Overloading, voltage spikes, and electromagnetic disturbance can all cause cables to fail. An electrical surge can erode insulation and cause short circuits. Overuse is another cause that reduces the life of cables and also leads to lousy grounding and electrical imbalances.

How Can We Protect Against Cable Damage In Hazardous Environments?

Preventing cable damage in hazardous environments requires a comprehensive approach. The following are some key strategies for protecting cables in harsh conditions.

1. Choose the Right Type of Cables

Make sure the cables selected are rated for hazardous environments. For instance, armored cables give extreme mechanical protection. Shielded cables reduce interference in high-electromagnetic environments, while heat-resistant cables resist extreme temperatures. The correct cable selection ensures that the cable lasts longer and works better.

2. Proper Cable Management

Cables should be routed to reduce tension and wear. Cable trays, conduits, and clamps should be used to hold cables in place for minimum movement. Routing cables along pre-identified paths reduces their exposure to hazards. Cabling also facilitates easy maintenance efficiency and minimizes handling errors that may cause damage.

3. Cables and Equipment Regular Inspection and Maintenance

Examine cables regularly for damage or wear. Scheduled maintenance due to early detection will give a lesser possibility of failure. Trained personnel should examine the cables for cracks, fraying, and insulation deterioration. A planned maintenance program can guarantee that the cables are in optimum condition and fail less suddenly.

4. Protection against Environmental Dangers

Use protective covers and sealants to protect cables from excessive heat, chemicals, or moisture. Applying good quality industrial insulation and weather-proof coatings will prevent early aging in the initial period. Install cable conduits or elevated ways that will save it from further exposure to the environment as well as from physical destruction.

Benefits of Preventive Measures

When implemented, these measures will not only avoid damage to the cables but also improve the efficiency and safety of operation. Companies that take initiatives for cable safety enjoy the following advantages.

Improved Safety: This reduces the rate of accidents associated with cable breakage. Good cable condition and safety ensure no electrical fire shock or equipment breakdown.

Cost Saving: It saves the costs of replacing the cables and also saves time from downtime. Preventive maintenance and proper installation will avoid costly repairs and loss of operation.

Increased Life Span: Proper care will extend the life of the cables. Fewer replacements occur in well-protected cables, reducing long-term costs and material wastage.

Performance Improvement: Good cables are always in top order and make the overall system more reliable. The equipment works more efficiently and has less power losses.

Conclusion

Preventing cable damage in hazardous environments will ensure safety, efficiency, and long-term cost savings. Regular checks, proper protection, and good-quality cables will all extend your wiring system’s lifespan. Proper cable management reduces downtime and the risk of accidents and equipment failure.

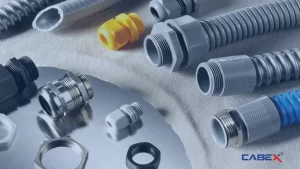

Reliable cables perform well even in the most challenging conditions. Cabex India provides the best-in-class products for the most demanding environments, ensuring durable and reliable cable protection solutions. Browse their range today to keep your cables safe and your operations running smoothly!

FAQs:

1. In dangerous operating conditions, what are the indicative symptoms of cable deterioration?

The visible indications include signs of distress by wear and tear, fraying and discoloration, and occasional malfunction. Burnt smells, sparks, and sudden shutdown are symptoms of internal faults and should be addressed immediately.

2. How often should cables be inspected?

It is recommended that inspections be done at least quarterly or even more frequently in hazardous situations. High-hazard industries such as chemical plants and construction areas should inspect their cables monthly in order to prevent potential hazards.

3. Can regular cables be used in hazardous environments with protective measures?

Although protective techniques assist, it is preferable to use wires made specially for dangerous situations. Such cables have more strengthened insulations, shieldings, and higher strength suitability in severe conditions.

4. What is cable routing that can prevent damage?

Correct routing can reduce the risk of cable damage in hazardous environments due to the absence of excessive bending and contact with dangerous materials. In addition, cables shall be avoided in places around sharp objects, high-traffic areas, and heat sources to enhance a longer lifespan.

5. Are there industry standards for cable protection in hazardous environments?

Standards like the IEC and the NEC guide the selection of cables and also their protection for such applications. Adherence to these rules makes industrial applications safe, reliable, and efficient.

Follow us:- Facebook, Instagram

You May Also Like: Comprehensive Cable Gland Size Chart for Your Needs , How to Identify Genuine Quality Brass Cable Glands Easily