Introduction:

The Function of the Earth Tag Washer is a crucial aspect of electrical systems, particularly in grounding and earthing applications. In this blog post, we will delve into the details of this essential component, exploring its purpose, working principle, and significance in ensuring electrical safety. So, let’s unravel the mysteries of the Earth Tag Washer!

Understanding Grounding and Earthing

To comprehend the function of the Earth Tag Washer, it’s essential to first grasp the concepts of grounding and earthing. Grounding refers to the connection of electrical circuits or equipment to the Earth’s conductive surface, ensuring electrical safety and minimizing the risk of electric shocks. Earthing, on the other hand, specifically refers to the act of connecting electrical systems to the Earth through conductive pathways.

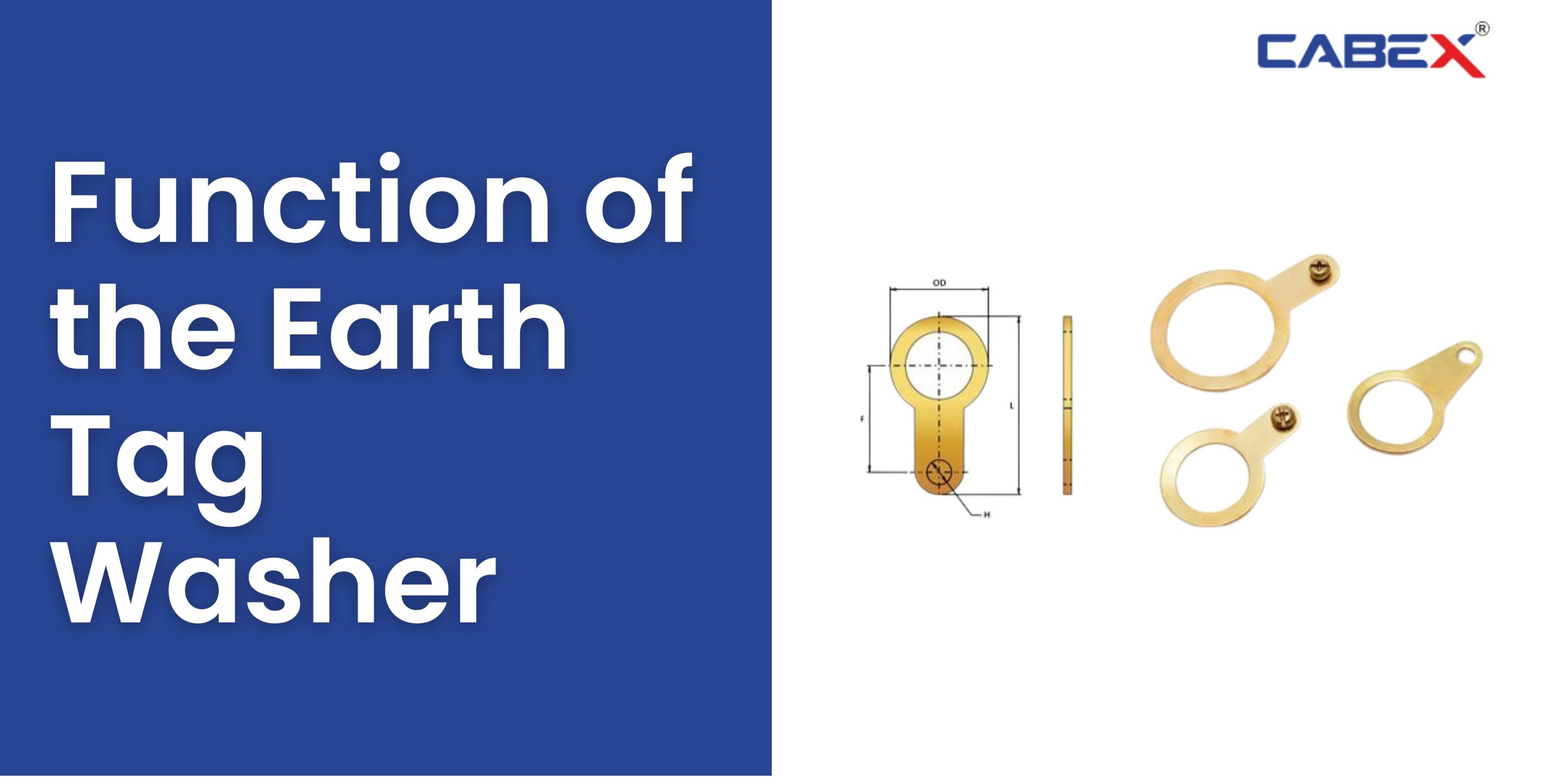

What Is an Earth Tag Washer?

An Earth Tag Washer is a specialized component used in grounding and earthing systems. It is a flat washer made of conductive materials such as copper or brass, designed to establish a secure connection between the electrical system and the Earth. The washer typically features a hole in the center, allowing it to be fastened securely to a panel, equipment, or structure.

The Purpose of Earth Tag Washers

The primary function of an Earth Tag Washer is to provide a reliable electrical connection between the grounding system and the Earth. This connection plays a vital role in diverting excess electrical current or fault currents to the Earth, effectively protecting individuals and equipment from electrical hazards. Earth Tag Washers ensure the longevity and effectiveness of the grounding system by maintaining a low-resistance path to the Earth.

Working Principle of Earth Tag Washers

When an electrical fault or surge occurs in a grounded system, the Earth Tag Washer acts as a path of least resistance, allowing the excess current to flow safely into the Earth. By offering a low-impedance pathway, the washer prevents the current from seeking alternative routes, which could result in electrical shock or equipment damage. The conductive materials used in Earth Tag Washers enable efficient and consistent grounding, ensuring the safety of both people and equipment.

Significance of Earth Tag Washers | Function of the Earth Tag Washer

Earth Tag Washers are critical components in electrical systems due to the following reasons:

1. Safety:

The Earth Tag Washer’s primary function is to provide a safe path for fault currents, reducing the risk of electrical shocks or fires.

2. Compliance:

Many electrical codes and regulations mandate the use of Earth Tag Washers in grounding systems to ensure compliance with safety standards.

3. Equipment Protection:

By establishing a reliable grounding connection, Earth Tag Washers safeguard electrical equipment from damage caused by electrical surges or faults.

4. Electrostatic Discharge (ESD) Protection:

Earth Tag Washers also contribute to protecting sensitive electronic devices from static electricity buildup and potential damage.

Installation Considerations for Earth Tag Washers

When installing Earth Tag Washers, several factors should be considered:

Material Selection: Choose Earth Tag Washers made from high-quality, corrosion-resistant materials such as copper or brass to ensure long-lasting performance.

Size and Shape: Select washers that match the equipment’s specifications and are compatible with the grounding conductor’s diameter.

Proper Positioning: Install Earth Tag Washers in locations specified by electrical codes, ensuring an effective connection between the equipment and the Earth.

Maintenance and Inspection

Regular maintenance and inspection are crucial to ensure the continued functionality of Earth Tag Washers. Here are some essential steps to consider:

Cleanliness:

Periodically clean the washers to remove dirt, dust, or corrosion, which may hinder their conductivity.

Tightness:

Check the tightness of the fasteners regularly to ensure a secure connection.

Visual Inspection:

Inspect Earth Tag Washers for signs of damage or degradation, such as cracks, discoloration, or deformation. Replace any defective washers promptly.

Different Types of Earth Tag Washers

When it comes to grounding systems, there are different types of Earth Tag Washers available to suit various applications and requirements. Let’s explore some of the common types of Earth Tag Washers:

1. Copper Earth Tag Washers:

Copper is a widely used material for Earth Tag Washers due to its excellent conductivity and corrosion resistance. Copper washers provide a reliable connection between the grounding system and the Earth, ensuring efficient grounding and minimizing the risk of electrical hazards.

2. Brass Earth Tag Washers:

Brass washers are another popular choice for grounding applications. They offer good conductivity and durability while providing resistance to corrosion. Brass Earth Tag Washers are suitable for both indoor and outdoor use, making them versatile in different environments.

3. Stainless Steel Earth Tag Washers:

Stainless steel washers are known for their high strength and resistance to corrosion. They are particularly suitable for harsh or corrosive environments where copper or brass may not be the ideal choice. Stainless steel Earth Tag Washers offer long-lasting performance and reliable grounding connections.

4. Tinned Copper Earth Tag Washers:

Tinned copper washers are copper washers coated with a thin layer of tin. The tin coating provides additional corrosion resistance, making them suitable for use in environments with high moisture levels or exposure to chemicals. Tinned copper Earth Tag Washers ensure a durable and effective grounding connection.

5. Galvanized Steel Earth Tag Washers:

Galvanized steel washers are made from steel coated with a layer of zinc. This zinc coating provides excellent corrosion resistance, making them suitable for outdoor applications where exposure to moisture and weather elements is a concern. Galvanized steel Earth Tag Washers are known for their durability and longevity.

6. Bi-Metal Earth Tag Washers:

Bi-metal washers are constructed using two different metals, typically copper and aluminum. These washers offer the advantage of combining the excellent conductivity of copper with the lightweight nature of aluminum. Bi-metal Earth Tag Washers are commonly used in applications where weight reduction or cost considerations are important factors.

It’s important to select the appropriate type of Earth Tag Washer based on the specific application, environment, and grounding requirements. Always refer to the manufacturer’s guidelines and relevant safety standards to ensure the proper selection and installation of Earth Tag Washers for your grounding system.

Case Studies

Present real-life case studies or examples where the proper use of Earth Tag Washers played a crucial role in preventing electrical hazards or equipment damage.

Conclusion:

The Function of the Earth Tag Washer is integral to the safety and reliability of grounding and earthing systems. By providing a low-resistance path to the Earth, these washers protect individuals and equipment from electrical hazards. Understanding the purpose, working principle, and significance of Earth Tag Washers is essential for maintaining a safe electrical environment. So, ensure that your electrical systems are properly grounded with the help of Earth Tag Washers, keeping electrical safety at the forefront of your mind.

Are you looking for high-quality Earth Tag Washers? Visit our website today to explore our wide range of electrical components and ensure the safety and effectiveness of your grounding systems

FAQ:

The function of a cable gland is to provide strain relief, secure cable entry points, and maintain environmental sealing for cables in electrical and industrial applications.

The earth wire is used for grounding electrical systems. It provides a safe path for fault currents to flow into the ground, preventing electric shocks and protecting equipment from damage.

Yes, gland plates need to be earthed. Earth connection ensures proper grounding and helps divert fault currents to protect against electrical hazards and equipment damage.

When a plate is earthed, it establishes a connection to the Earth, allowing excess electrical current or faults to be safely redirected, minimizing the risk of electrical shocks or damage.

Cable glands are earthed to ensure proper grounding of cables, preventing electrical shocks and protecting against the buildup of static electricity or potential discharge that could damage equipment or pose safety hazards.